Class 1 div. 1 electrical wiring

Built on superb customer service, we offer creative solutions to suit the individual needs of our customers. We strive to see things from the client point of view so we can understand and help achieve their goals. We are flexible, we listen, and we offer customized packages designed to work for you.

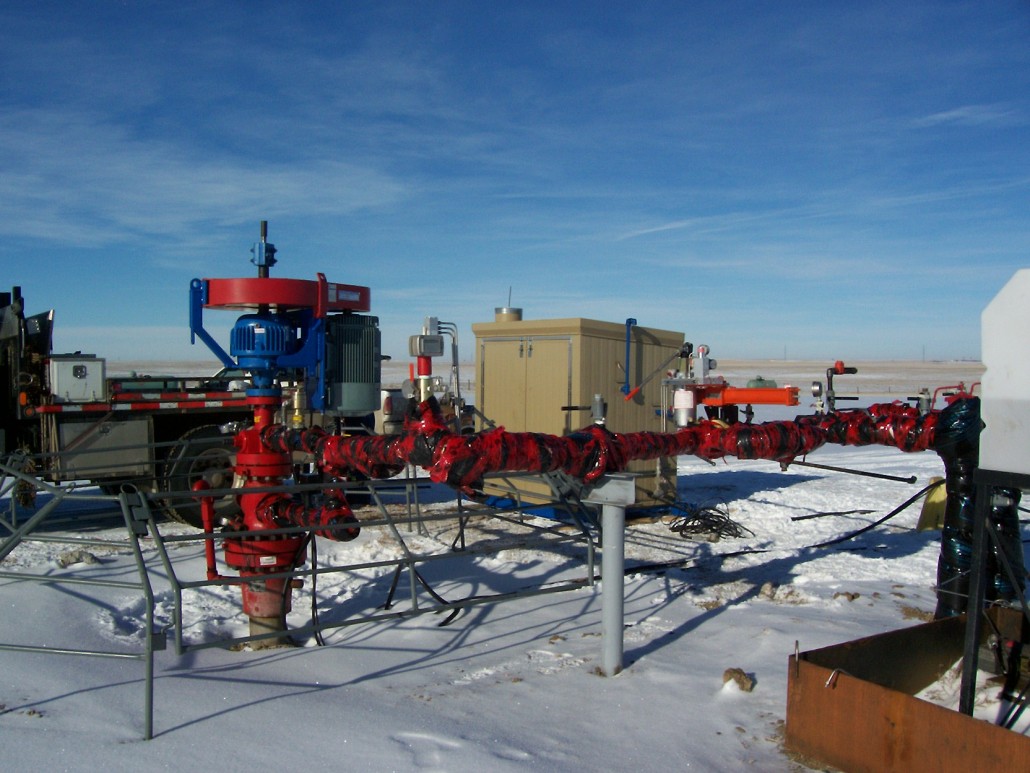

Well Site Compression

Oil Well Optimization

Natural Gas Boosters

Gas Gathering

Coal Bed Methane

Vapour Recovery

Sour Gas Compression

Solution Gas Compression

Why We’re Different

| BENEFIT | FEATURE |

| Anti-Vibration System | Prolongs the life of the compressor component |

| 100% Recycle | Compensates for daily gas flow fluctuations |

| Over Designed Scrubbers | Ensures all liquids/debris are removed |

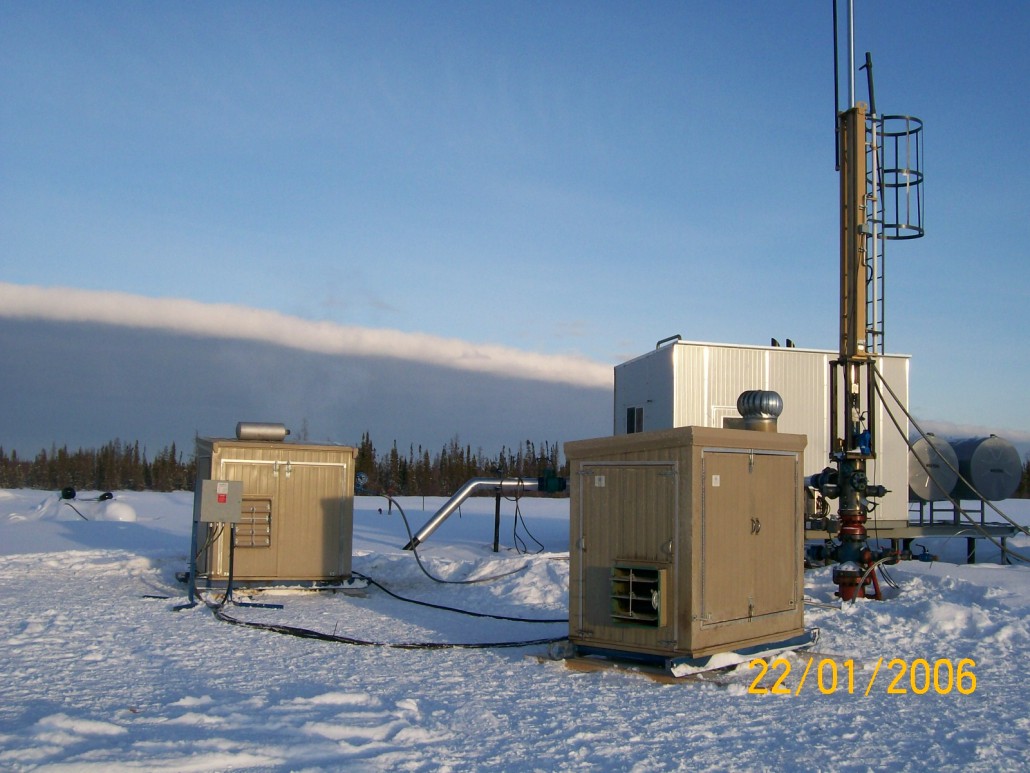

| Variable Cooling | Maintains optimal temperature year-round |

| No Freeze Heating System | Heat trace and heaters are standard |

| Double Check Valves | Safely re-inject compressed gas back into emulsion |

| Easy Start-up | Single button start up |

| Class 1 Division 1 Electrical | Control panel in compliance with classification |

| Electrical Panel/Starter | Displays running conditions, alarms and shutdowns |

| GFI Breaker | Protects Class 1 div 1 heat trace to wellhead |

| Hoses and Fittings Included | Connects with wellheads, treaters and tanks. Eliminates costs and inconvenience. |

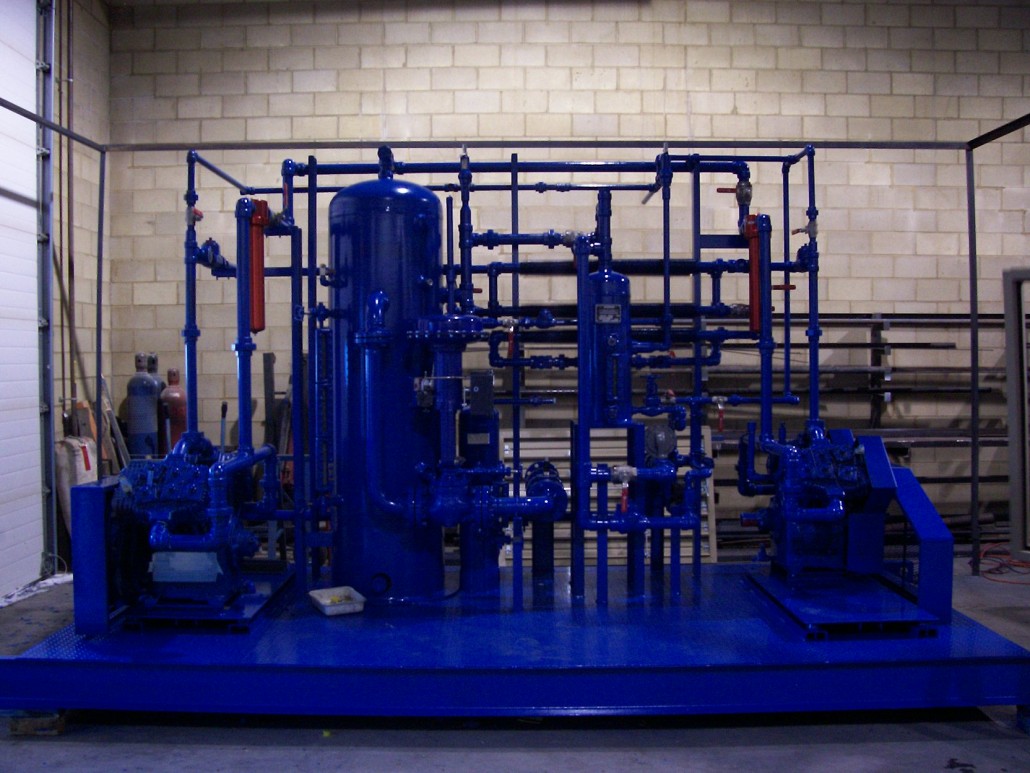

Casing Gas Compressor Specifications

| Driver | Electrical motor: 15HP / 30HP / 460v Three Phase XP |

| Compressor | Reciprocating QRNG / Hycomp Two Stage / Blackmer- Belt-driven with fan and aftercooler |

| Inlet Scrubber | 10” x 32” c/w demister pad CRN: OH3917.21345 for AB, B.C, SK, and MB |

| Inlet | Set @ 20 PSIG |

| Recycle Valve | Set @ PSIG |

| Shutdowns | High discharge temp. and pressure High suction pressure High scrubber liquid level Low compressor oil pressure |

| Visual Indicators | Suction pressure/casing pressure Discharge pressure Compressor oil pressure Discharge temp. (before and after cooler) |

| Oilfield skid | 50” wide x 78” long |

| Building | 50” wide x 78” long x 72” high R12 insulated aluminum Two 30” access doors One 18” x 18” intake louver One 24” x 24” discharge louver Aluminum panel interior |

| Electrical | Class 1 div. 1 Group C & D wired to off-skid control box – CSA ESD on skid Easy one button push start Heater and heat trace for suction and discharge lines |

Our products are designed and constructed to exceed all safety and production guidelines: